brinell hardness test and rockwell hardness test|disadvantages of rockwell hardness test : dealer In the Brinell Hardness Testing, the hardness of a metal is determined by measuring the permanent indentation size produced by an indenter. The Brinell Hardness Test method is the . Tyger! Tyger! burning bright In the forests of the night, What immortal hand or eye Could frame thy fearful symmetry? In what distant deeps or skies Burnt the fire . Ver mais

{plog:ftitle_list}

Resultado da 9 de fev. de 2024 · Ele é um redator de currículos profissional certificado (CPRW) desde 2021 e busca ajudar no desenvolvimento profissional de .

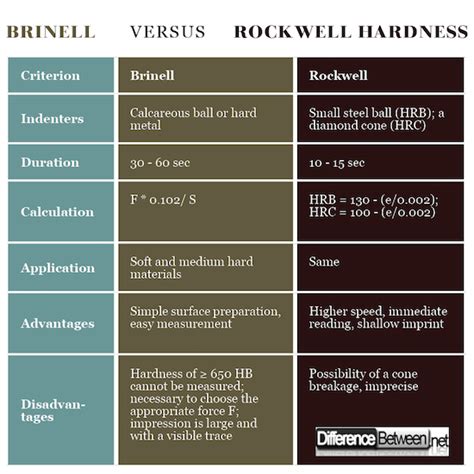

Summary of Brinell Verses Rockwell Hardness. The Brinell and Rockwell methods fall into the group of statistical methods of hardness testing. Each method has its unique purpose, .In this article, our seasoned expert, Lee Mangham, will guide you through the differences between the Brinell and Rockwell hardness tests, including their methods, advantages, differences, and practical significance in evaluating . Brinell test is better than the Rockwell hardness test because it can measure the hardness of though material which is not measurable by another test like Rockwell. Brinell test .

iphone 8 plus vs galaxy s8 plus drop test

In the Brinell Hardness Testing, the hardness of a metal is determined by measuring the permanent indentation size produced by an indenter. The Brinell Hardness Test method is the .The Rockwell, Brinell, and Vickers hardness testing methods are generally used for different scenarios and situations. However, hardness testing professionals have sometimes found it .

Among the various hardness testing methods, the Brinell and Rockwell tests are two of the most commonly used techniques. In this article, we will compare these two methods, highlighting their differences and applications. The three most well known and widely used hardness tests for metals today are Brinell, Rockwell, and Vickers. Here are the basic differences explained.A chart is then used to convert the averaged diameter measurement to a Brinell hardness number. Test forces range from 500 to 3000 kgf. A Brinell hardness result measures the permanent width of indentation produced by a carbide .

Difference between, Brinell,Rockwell and Vickers Hardness Test What is Hardness? Hardness is the property of a material that enables it to resist plasticThis article details the Brinell to Rockwell hardness conversion chart, which explains how the test results of one scale can be translated into another. + 86 755 61301520; [email protected]; . Rockwell hardness testing has several uses in industries like construction, manufacturing, oil and gas, automotive, etc. .

Hardness Methods: The Rockwell hardness test measures the depth of penetra-tion of an indenter into a material under a known load. It provides a hardness value based on the depth of penetration. Rockwell Hardness The Brinell hardness test involves indenting a material with a hard sphere under a specific load. Two diameters (x and y ASTM E384: This standard is for hardness testing on a micro-scale, and therefore includes the Vickers and Knoop hardness tests. ISO 6506: This standard mirrors ASTM E10, as it contains the standard method for measuring the Brinell hardness of metals. ISO 6507: This standard contains the details for the Vickers hardness test in metallic materials. When the Brinell hardness test cannot be used, such as when the material’s HB value is greater than 450 or the sample size is too small, the Rockwell hardness test is used instead. This test involves pressing either a diamond cone with a top angle of 120° or a steel ball with a diameter of 1.59 mm or 3.18 mm into the surface of the tested .For instance, converting from a Rockwell hardness test on the C scale (HRC) to a Brinell hardness test value requires using the formula: BHN = 5.970 x (HRC + 104.7). This formula gives an approximate value for the Brinell hardness value, and quality assessment professionals use it to create the conversion tables and charts for instant conversion.

These approximate relationships between hardness and tensile strength do not apply to nonferrous metals, with the possible exception of certain aluminum alloys. Related: Brinell Hardness Testing Equation. Table A Brinell Hardness to . The Rockwell and Brinell hardness tests are performed using a hardness tester (United Testing Systems, True-Blue Universal), according to ASTM E18 [] and E10 [], respectively.A carbide indenter ball with a diameter of 1.59 mm is employed to make an indentation on the surface of a sample.

To wrap up, knowing the best-suited hardness test of the three, Rockwell, Brinell, and Vickers, for your hardness test will require that you understand the determining criteria for employing any hardness test. In the final analysis, the type of material and the environment where the test will take place will significantly determine the best .

Conducting a hardness test using the Rockwell hardness method can be difficult, especially if you misunderstand its principles and application. Not to overstate it, but without an understanding of the Rockwell hardness method, you might end up going round in circles or, worse still, end up with an inaccurate material hardness value.The Rockwell hardness test is applied globally for the application of an experimental indentation hardness test. The Rockwell test is a quick process, very cost-effective, and non-destructive test (causing only minor indentation on the specimen material). The Rockwell hardness test is a simple process that is why it can be performed by anyone . The Rockwell hardness test involves applying a sequence of loads to the material and measuring the depth of the resulting indentation, which indicates the material’s hardness. . Brinell Hardness Test. The Brinell hardness test is ideal for measuring the hardness of metals with coarse or inhomogeneous grain structures, such as cast iron and .

All information about Brinell hardness testing Test procedure Sample request for the Brinell method Brinell hardness Discover now. . The process is slow (by comparison with the Rockwell method). The test cycle takes somewhere between 30 and 60 seconds, not including the time taken to prepare the specimen.Macro-Hardness (Rockwell and Brinell) testing is the most commonly applied materials test in industry due to several factors: 1) Macro-Hardness Testing is simple to perform and does not require highly skilled operators; 2) Through the use of different loads and indenters, hardness testing can be used for determining theLearn all you need to know about Rockwell hardness testing – including test definitions, test calculations and insight into Rockwell hardness testing machines and HRC hardness testers – with knowledge and expertise from .

Hardness testing is a crucial method for evaluating the mechanical properties of materials. It helps determine a material's resistance to deformation, wear, and scratching. Among the various hardness testing .Brinell vs Rockwell Hardness. The Brinell hardness test involves pressing a tungsten carbide ball of a specific diameter into the surface of the material being tested with a predetermined force. The Rockwell hardness test uses a hardened steel ball of a specific size that is pressed Into the material under a specified load.DEFINITION OF THE BRINELL HARDNESS TEST The Brinell hardness test was originally developed in the late 1800s by the Swedish engineer of the same name. He wanted to find a method to control the quality/hardness of steel. His solution was to press a railway wheel-bearing ball into the material and then measure the size of the mark it left.

The Brinell hardness is designated by the most commonly used test standards (ASTM E10-14 [2] and ISO 6506–1:2005) as HBW (H from hardness, B from brinell and W from the material of the indenter, tungsten (wolfram) carbide). In former standards HB or HBS were used to refer to measurements made with steel indenters.

The Rockwell hardness test. Rockwell is a fast hardness test method developed for production control, with a direct readout, mainly used for metallic materials. . The Brinell hardness test is used for hardness testing larger samples in materials with a coarse or inhomogeneous grain structure. The Brinell hardness test (HBW) indentation leaves .In the Rockwell hardness test, a differential-depth method, the residual depth of the indent made by the indenter, is measured.In contrast, the size of the indentation is measured in the Brinell, Vickers and Knoop optical test methods.. The deeper a defined indenter penetrates the surface of a specimen with a specified test load, the softer the material that is being tested.

Indentation hardness value is obtained by measuring the depth or the area of the indentation using one of over 12 different test methods. Learn more about hardness testing basics here. The Rockwell hardness test method, as defined in ASTM E-18, is the most commonly used hardness test method. You should obtain a copy of this standard, read and . 1.3 The portable hardness testers covered by this test method are verified only by the indirect verification method. Although the portable hardness testers are designed to employ the same test conditions as those defined in the standard test methods, the forces applied by the portable Rockwell and Brinell testers and the depth measuring systems of the portable .This eLearning course focuses on Rockwell and Brinell hardness testing and Vickers and Knoop microhardness testing. Participants will learn about how the tests are performed, test sample requirements, test parameter selection, and testing requirements. The course can be completed in 30 minutes. The ratio of testing force \(F\) and the indentation surface \(A\) (spherical segment) serves as a measure for the Brinell hardness value HBW: \begin{align} \label{brinellhaerte} &HBW=\frac{0.102 \cdot F}{A} \[5px] \end{align} Figure: Brinell hardness test procedure. With the Brinell hardness test, a carbide ball is pressed into the material.

Brinell Hardness Tester holds significant importance in today's industrial landscape, where understanding material properties is crucial for ensuring product quality, reliability, and performance. This test reveals vital information about their hardness, toughness, and suitability for specific applications by subjecting materials to controlled indentation.

rockwell vs brinell hardness test

A senior X é a plataforma que vai elevar a gestão das empresas. Uma tecnologia 100% cloud, integrada e flexível para cada modelo de negócio. Apenas com ela você tem todas essas vantagens: Principais vantagens .

brinell hardness test and rockwell hardness test|disadvantages of rockwell hardness test